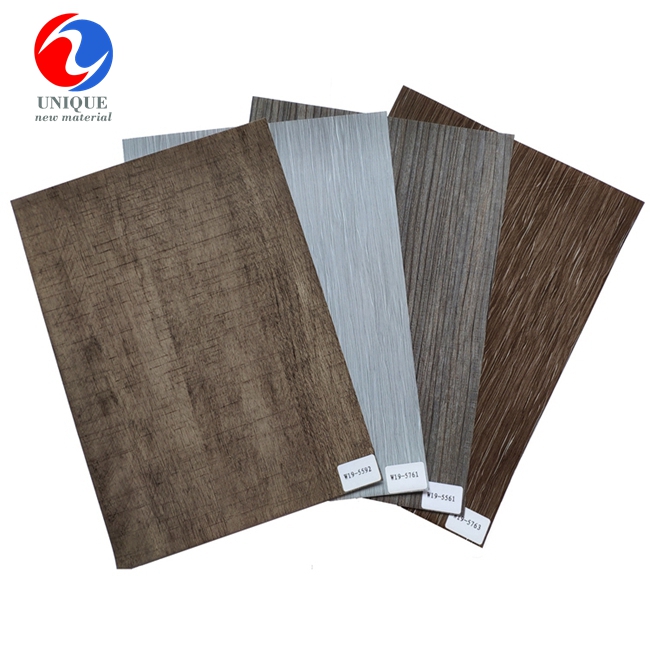

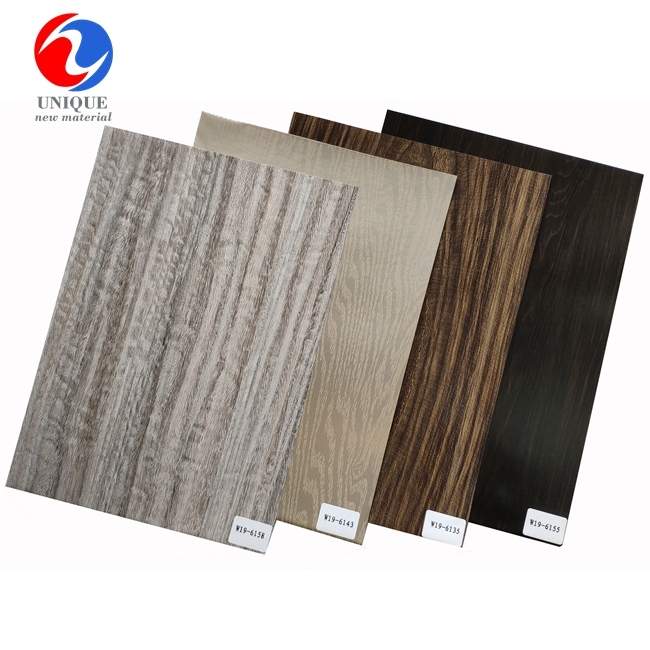

Wood Pattern Finish Hot Stamping Foil For MDF WPC PVC Plastic

Wood Pattern Finish Hot Stamping Foil For MDF WPC PVC Plastic adopts hot melt adhesive, colorless transparent or light yellow sticky liquid, after dried into foil, the base foil is transparent, on the coated release agent and ink surface, with excellent composite fastness and excellent flexibility, abrasion resistance, strong resistance to water, acid and alkali performance. Realistic surface texture, bright color, no color difference, close to nature. The product surface transfer process is simple and efficient. Product surface can do UV coating after transfer. The hot stamping substrate does not contain formaldehyde, or any other toxic, harmful substances, with excellent environmental performance.

Features: delicate texture, clear and vivid, has a strong sense of three-dimensional effect, wood imitation; high opacity, strong adhesion, wear resistance and corrosion resistance etc.

Stamping roller temperature: 160-220 ℃

Heat transfer speed: 5-10 m/min

Pressure: 4-5 bar

Place of Origin: | Qingdao, Shandong Province, China |

Brand Name | Unique |

Material | PET |

Application | Hot Stamping Foil For MDF WPC PVC Plastic |

Film thickness | 18-20microns |

Total thickness | 23-25microns |

Roll size | 0.64X500m |

Usage | Hot stamping |

Packing method | Bubble film+ OPP bag + Kraft paper carton+ pallet |

Delivery | 5-7 days |

Application:

Floor, furniture board, skirting, door frame hot stamping foil

Usage: 1. clean the surface: clean the substrate surface, remove dust and greasy, etc..

2. Pull out and flatten the MDF film, put it on the stamping machine.

Avoid MDF board and the film from wrinkled.

<<Previous page

Next page >>